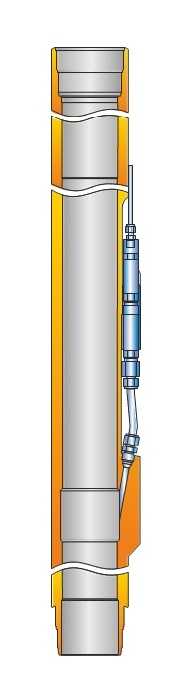

CHEMICAL INJECTION NIPPLE C/W DUAL CHECK & RUPTURE CARTRIDGE (SINGLE / DUAL INJECTION PORT)

Actinc usa

2018-03-15T10:15:08+00:00

CHEMICAL INJECTION NIPPLE C/W DUAL CHECK & RUPTURE CARTRIDGE (SINGLE / DUAL INJECTION PORT)

ACT Chemical Injection Nipple represents a complete solution to any application requiring downhole chemical injection. At the heart of the chemical injection nipple is the dual check valve and rupture cartridge assembly. This allows the chemical injection nipple to be run in hole in a ‘blanked condition’ and selectively opened for injection, with the application of the required shear pressure. The optional control line by-pass facility allows encapsulated control lines to pass interrupted through the chemical injection nipple. The chemical injection nipple can be supplied with a variety of profiles to allow for the installation of many standard flow control devices, such as blanking plugs, checks and chokes. These optional profiles also allow installation of the specifically designed separation sleeve, which provides a secondary method of isolating the chemical injection flow path from the tubing.

FEATURES AND BENEFITS:

-

Burst, collapse, tensile and torque ratings as good as end connection

-

Compact, modular design

-

Metal to metal sealing connections throughout

-

Optional nipple profiles provide all the flexibility and benefits of flow control equipment

-

Removable rupture cartridge allows full pressure and flow testing prior to running

-

Rupture cartridge can be supplied with a variety of shear pressures to suit customer requirements

-

Optional by-pass facility permits installation and protection of encapsulated control lines