MODEL ‘D’ & ‘F’ PERMANENT PACKERS

Actinc usa

2018-12-06T05:01:39+00:00

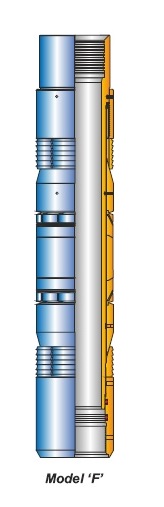

MODEL ‘D’ & ‘F’ PERMANENT PACKERS

The ACT Model ‘D’ & ‘F’ Production Packers are available to fit your needs and provide the versatility of our excellent pack-off system for a positive secure set in the well bore. These packers assist in the economical operation of a variety of completion and production jobs. These are designed to accommodate seal bore extensions used in deep wells requiring a longer seal bore interval. Seal Nipples are available with either automatic square-thread latch or locating shoulder. These packers can be used as test tools. Full opening bores allow the passage of perforating guns used to perforate a zone below for testing. If the zone proves to be non-productive, the packer can be used as a squeeze tool. The packers are designed to provide high-impact resistance and a dependable seal. The high quality packing system will conform to the casing and close off any extrusion of rubber, as the packer is set, even at high temperatures and pressures. ACT Model ‘D’ Production Packers provide excellent clearance for run-in while the ACT Model ‘F’ Production Packers offer a larger seal bore. The two models carry different pressure ratings noted later in this document. R22 is the designation for standard service that ACT puts on the equipment listed below. Equipment for service other than standard can be specified upon request from the customer. For additional information, please contact ACT or an authorised representative.

Features:

-

One piece slips hardened to depth of wicker only

-

Sets in any grade casing including P-10

-

Choice of bottom to fit your application – specified when ordering

-

Re-attaching lock ring holds setting force

| MODEL ‘D’ SPECIFICATION GUIDE Rated 10,000 psi @ 300 Degrees F |

| CASING |

SETTING RANGE |

PACKER DATA |

SEAL ASSY. |

| OD |

Wt./ft. |

Min. |

Max. |

Max. OD |

Thd. Dia. |

Seal Bore |

Part No. |

Size |

Size |

ID Thru |

| 4.1/2 |

9.5-13.5 |

3.920 |

4.090 |

3.750 |

3.250 |

2.687 |

070-3750-100* |

37-26 |

40-26 |

1.937 |

| 5 |

15-21 |

4.125 |

4.436 |

3.968 |

3.250 |

2.687 |

070-3968-100* |

39-26 |

40-26 |

1.937 |

| 5.1/2 |

20-23 |

4.625 |

4.811 |

4.328 |

3.250 |

2.687 |

070-4328-000 |

43-26 |

40-26 |

1.937 |

| 5.1/2 |

13-17 |

4.812 |

5.044 |

4.500 |

3.250 |

2.687 |

070-4500-000 |

45-26 |

40-26 |

1.937 |

| 6 |

14-26 |

5.140 |

5.552 |

4.937 |

3.500 |

3.000 |

070-4937-100** |

49-30 |

42/62-30 |

2.375 |

| 6.5/8 |

17-20 |

6.049 |

6.366 |

5.687 |

4.000 |

3.250 |

070-5687-000 |

56-32 |

80-32 |

2.375 |

| 7 |

23-32 |

6.049 |

6.366 |

5.687 |

4.000 |

3.250 |

070-5687-000 |

56-32 |

80-32 |

2.375 |

| 7 |

17-20 |

6.456 |

6.765 |

6.187 |

4.000 |

3.250 |

070-6187-000 |

61-32 |

80-32 |

2.375 |

| 7.5/8 |

33.7-39 |

6.456 |

6.765 |

6.187 |

4.000 |

3.250 |

070-6187-000 |

61-32 |

80-32 |

2.375 |

| 8.5/8 |

36-49 |

7.500 |

7.825 |

7.125 |

4.500 |

4.000 |

070-7125-000** |

71-40 |

80-40 |

3.000 |

| 9.5/8 |

29.3-53.5 |

8.438 |

9.063 |

8.125 |

4.000 |

3.250 |

070-8125-000 |

81-32 |

190-32 |

2.375 |

| 9.5/8 |

29.3-53.5 |

8.438 |

9.063 |

8.125 |

4.500 |

4.000 |

070-8125-060 |

81-40 |

80-40 |

3.000 |

- Rated 7,500 psi @ 300 degrees with HRC 18-22 Steel Body (Standard).

- Rated 10,000 psi @ 300 degrees with HRC 28-32 Steel Body (Optional). Specify when ordering.

| MODEL ‘F’ SPECIFICATION GUIDE Rated 7,500 psi @ 300 Degrees F |

| CASING |

SETTING RANGE |

PACKER DATA |

SEAL ASSY. |

| OD |

Wt./ft. |

Min. |

Max. |

Max. OD |

Thd. Dia. |

Seal Bore |

Part No. |

Size |

Size |

ID Thru |

| 5.1/2 |

20-23 |

4.625 |

4.811 |

4.437 |

3.500 |

3.000 |

080-4437-100 |

44-30 |

42/62-30 |

2.375 |

| 5.1/2 |

14-17 |

4.812 |

5.012 |

4.562 |

3.500 |

3.00 |

0080-4562-100 |

45-30 |

42/62-30 |

2.375 |

| 5.1/2 |

13-14 |

4.976 |

5.126 |

4.750 |

3.500 |

3.000 |

080-4750-100 |

47-30 |

42/62-30 |

2.375 |

| 6.5/8 |

20-24 |

5.875 |

6.094 |

5.687 |

4.500 |

4.000 |

080-5687-100 |

56-40 |

80-40 |

3.000 |

| 7 |

32-38 |

5.875 |

6.094 |

5.687 |

4.500 |

4.000 |

080-5687-100 |

56-40 |

80-40 |

3.000 |

| 6.5/8 |

17 |

6.095 |

6.276 |

5.875 |

4.500 |

4.000 |

080-5875-000 |

58-40 |

80-40 |

3.000 |

| 7 |

26-29 |

6.095 |

6.276 |

5.875 |

4.500 |

4.000 |

080-5875-000 |

58-40 |

80-40 |

3.000 |

| 7 |

20-23 |

6.277 |

6.456 |

6.000 |

4.500 |

4.000 |

080-6000-000 |

60-40 |

80-40 |

3.000 |

| 7 |

17-20 |

6.456 |

6.765 |

6.250 |

4.500 |

4.000 |

080-6250-000 |

62-40 |

80-40 |

3.000 |

| 7.5/8 |

33.7-42.8 |

6.456 |

6.765 |

6.250 |

4.500 |

4.000 |

080-6250-000 |

62-40 |

80-40 |

3.000 |

- The shoe type must be specified upon placing sales order

- The figures contained herein are subject to change without notice.