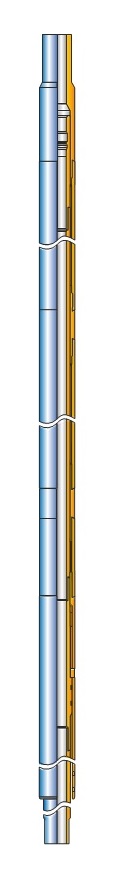

OVERSHOT EXPANSION JOINT(OEJ) ASSEMBLY

ACT Overshot Expansion Joint (OEJ) Assembly is designed for applications where extreme tubing movements are expected due to stimulation or production of the well and when a tubing separation device is also required.

The OEJ assembly is a one-trip system, which allows the well to be flanged up prior to setting the packer. The OEJ assembly incorporates a slick joint sub as well as housing – packing set including working seal units and a debris barrier above the working seals. The plain receptacle, housing – packing set and seals can be retrieved when the tubing string is recovered for maintenance or the entire completion can be retrieved by straight pull after ensuring that J-pin engaged with J-slot, thus allowing the packer to be retrieved.

The OEJ assembly is available in varying lengths of up to 20 ft. stroke. Adjustable shear pins lock the inner & outer assembly together during run-in. Once the shear screw gets sheared by applying load, the outer assembly gets disengaged and it is free to move on the inner assembly, compensating for tubing movement.

FEATURES:

-

One-trip required to run in and actuate

-

Available in stroke lengths up to 20 ft.

-

Debris barrier above the working seals

-

Seating nipple located at the upper end of the slick joint sub

-

Seals can be retrieved for redress

-

One-trip retrieval – J-pin J-slot assembly allows the entire completion to be retrieved with straight pick up of the tubing once engaged

BENEFITS:

-

No tubing manipulation required to set

-

One-trip system saves rig time

-

Seals can be retrieved for redress without removing packer

APPLICATIONS:

Completions in which the packer is set after the well is flanged up.

SPECIFICATIONS:

| OVERSHOT EXPANSION JOINT(OEJ) ASSEMBLY | |||||||

|---|---|---|---|---|---|---|---|

| TUBING | RUN IN CASTING | MAX OD | NIPPLE SEAL BORE | STROKE | W.P | ||

| OD (inch) | WT (Ibs/ft) | SIZE (inch) | WT (Ibs/ft) | (inch) | (inch | (FT) | (Psi) |

| 2.3/8 | 4.7 | 4.1/2 | 11.6-15.1 | 3.60 | 1.875 | 15 up / 5 down = 20 total 7.5 up / 7.5 down = 15 total 5 up / 5 down = 10 total | 5000 |

| 2.3/8 | 4.7 | 4.1/2 | 15.1-20 | 3.50 | 1.875 | 5000 | |

| 2.7/8 | 6.5 | 5.1/2 | 20-23 | 4.50 | 2.313 | 7500 | |

| 3.1/2 | 9.3 | 7 | 32-38 | 5.65 | 2.813 | 7500 | |

| 4.1/2 | 12.75 | 7.5/8 | 24-33.70 | 6.50 | 3.813 | 7500 | |

- OTIS type “X” size given; however OTIS “R” type & Baker “F” type profile can also be provided

- Top box X bottom pin EUE 8 RD Connection / customer to specify tubing Connection

- W.P. = T.P