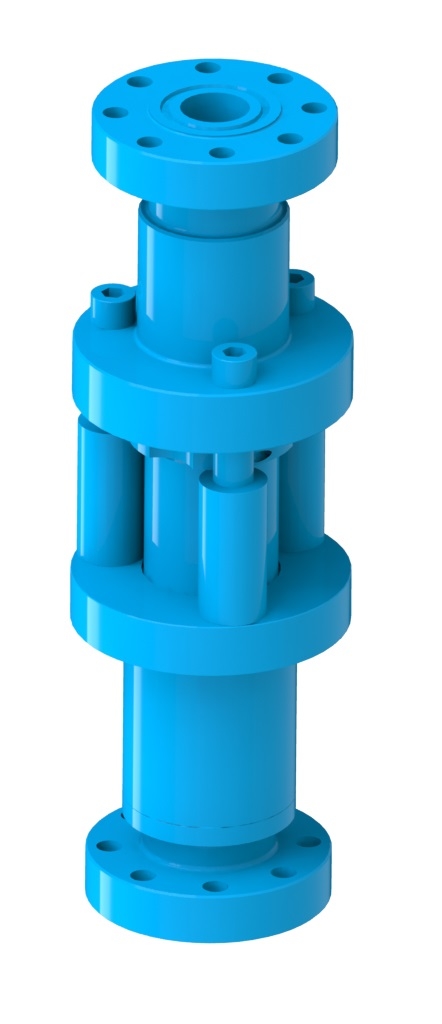

SIDE LOADING STRIPPER PACKER

Actinc usa

2018-04-19T09:48:55+00:00

SIDE LOADING STRIPPER PACKER

FEATURES

The ACT coiled tubing Side Loading Stripper/Packer is designed for use with injectors built by various manufacturers. The significant single feature of the ACT Side Loading Stripper/Packer is that it offers field replacement of the interlock packer, non- extrusion ring, and bushings through the side door, below the injector and with tubing in the well.

Additional features:

-

The union sub and nut are field

-

The union nut can be ‘latched up’, while stabbing the union sub into the BOP

-

Optimum tubing column support with tubing sizes 00, 1.25,1.50, and 1.75 available.

-

A unique three point tie rod arrangement provides a significantly greater working space within the side loading door clearance opening for enhanced field replacement of the vital sealing components and

-

The piston “close” and “open” ports are NPT and both are located below the door clearance.

-

Key components are 17-4 PH stainless steel or alloy steel for optimum strength and corrosion Bushings are of aluminium bronze.

-

Below the door energizer piston arrangement does not move the critical upper tubing bushings. This unique arrangement provides continuous, non-changing tubing column support.

-

Convenient NPT gauge / injection

-

Interlock packer and non – extrusion ring are interchangeable with Various materials are available to suit specific well /service conditions.

-

Glass – filled teflon non – extrusion ring provide an optimum interlock packer support / reliability.

-

The four hydraulic control supply ports are of NPT which require no special.

-

A unique “breach lock” style lock flange provides reliable safety of door closure yet offers easy field

-

The piston is situated below the packer element. Having the piston in this position will decrease the amount of hydraulic pressure required to pack-off around the Coiled.

OPERATING PARAMETERS

Assembly Working Pressure : 10,000 PSI

Test Pressure…. : 15,000 PSI

Hydraulic Operating Pressures

Piston Close (Packing – off) : 5,000 PSI

Max Piston Open (Relaxing Packer) : 5,000 PSI

Max Door Close : 3,000 PSI Max

Door Open : 3,000 PSI Max