GATE VALVES

Actinc usa

2018-12-04T10:34:02+00:00

EXPANDING STYLE GATE VALVE

ACT manufactured Gate Valves required for drilling and production operation.

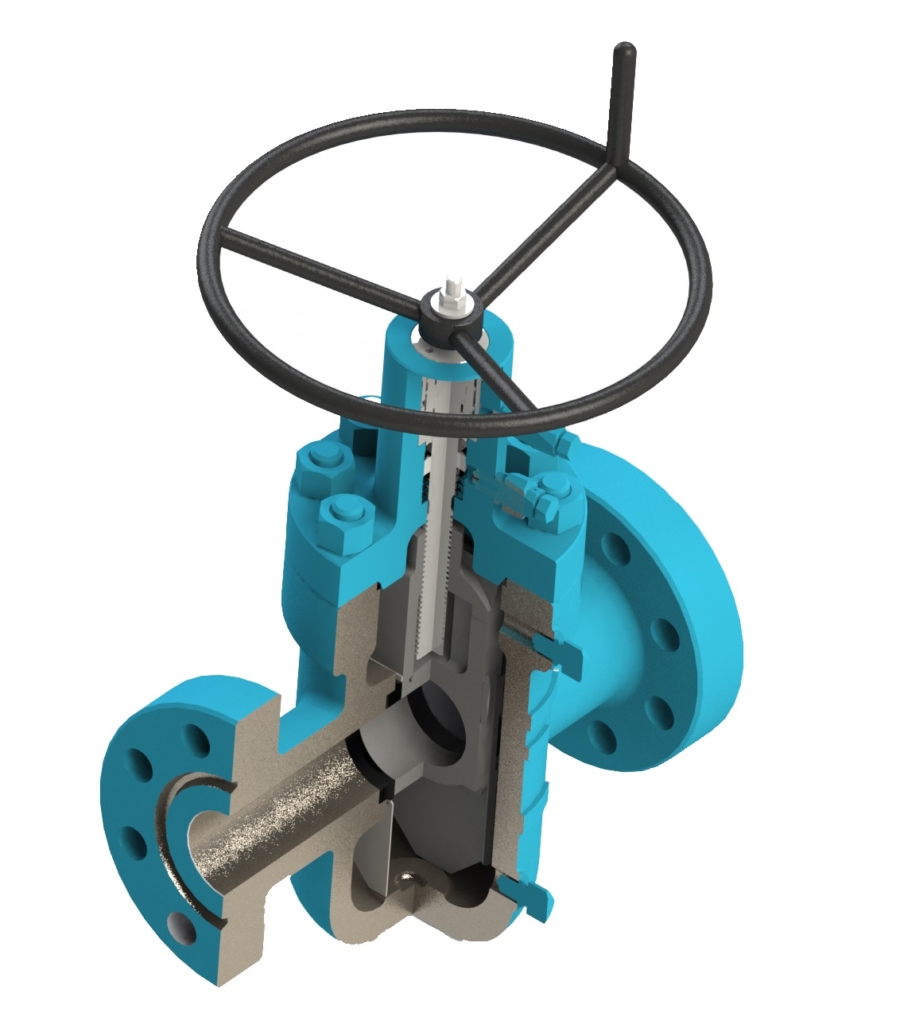

ACT EXPANDING GATE VALVE MODEL ‘ M ‘ :

-

Full bore through conduit

-

Block and Bleed Mechanism

-

Long-life seat

-

Positive Seal by Expand Mechanism

-

In- line maintenance

-

Non- Rising and Non- Balanced Stem

-

Thrust bearing for the low torque operation

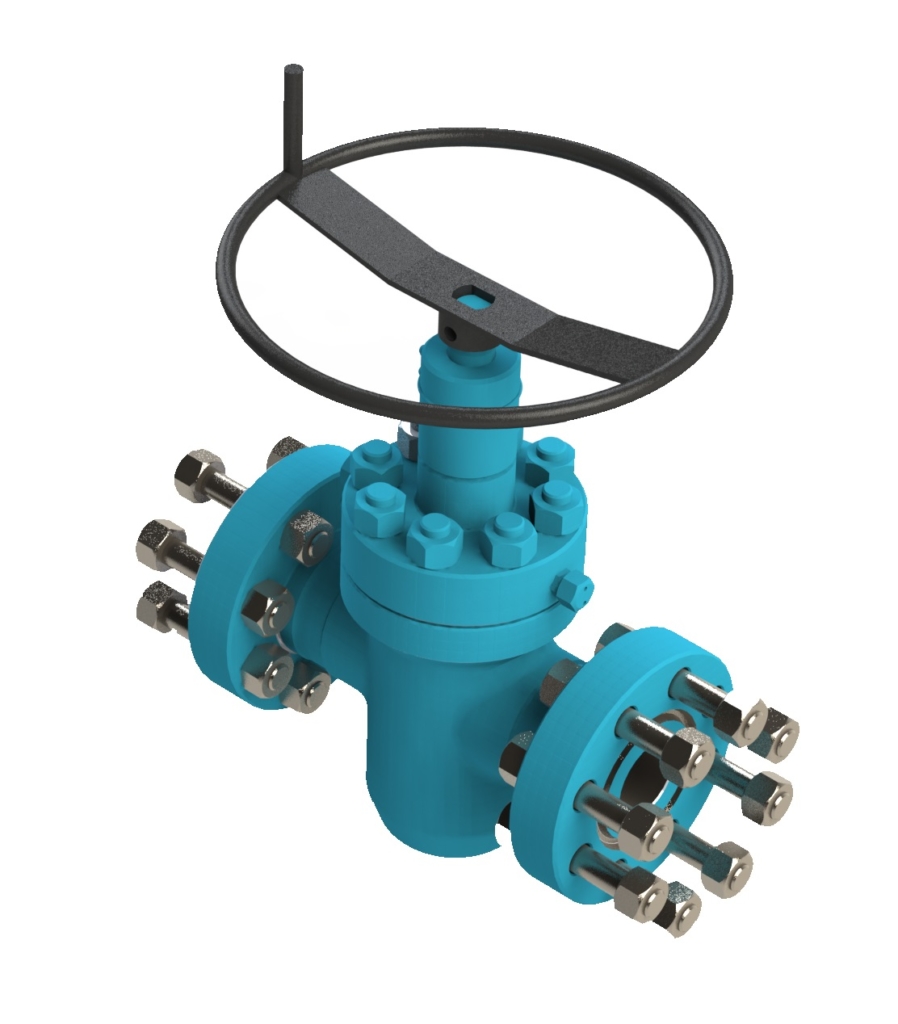

SLAB STYLE GATE VALVE

Main features:

-

Full bore through conduit

-

Block and Bleed Mechanism

-

Floating seat with self relief function

-

In-line maintenance

-

Metal to Metal sealing

-

Metal to Metal stem back seat

-

Heavy duty bearing for low torque and easy operation

-

Non-Rising and Non-Balanced Stem

-

Forged Body and Bonnet Construction

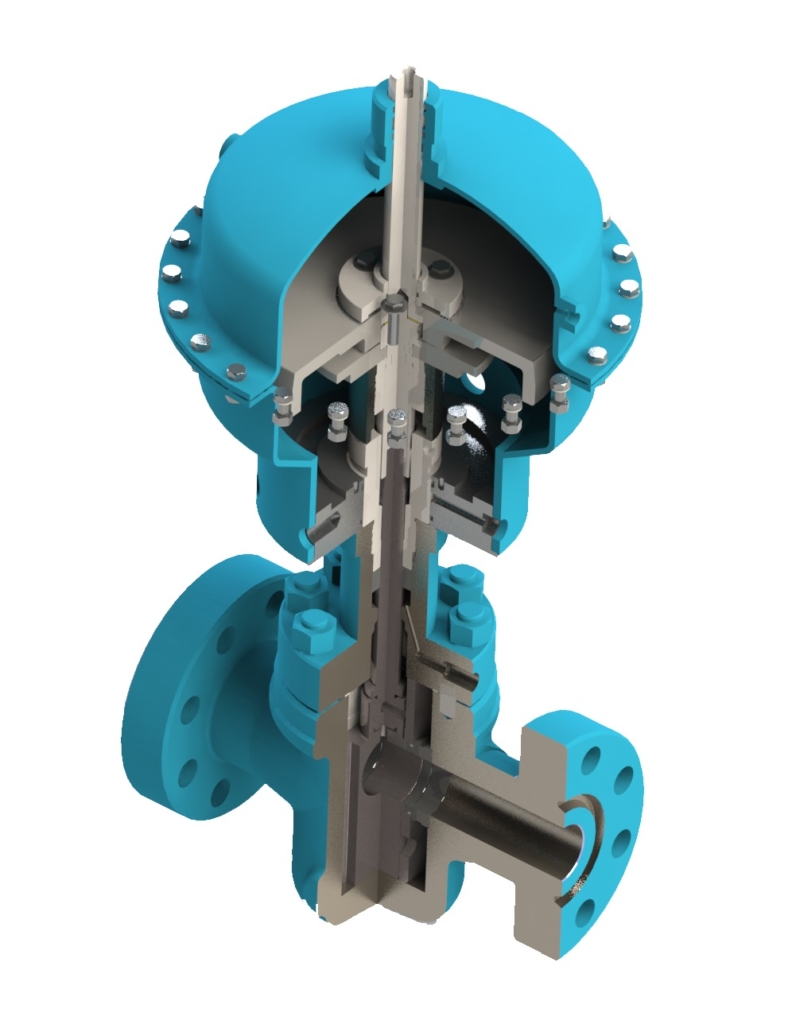

PNEUMATIC DIAPHRAGM OPERATED GATE VALVE

Pneumatic Diaphragm Gate Valve have less friction, close-open quickly, long life and dependable sealing. It could be a SSV (Surface Safety Valve) with Induction System, driven by compressed air. When fluid pressure in pipeline has some troubles, it will be auto off, and it could auto off main valve while controlling system pressure blabbed. This valve has been installed with the manual pressure relief device, over pressure auto protector and manual operated device.

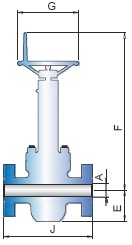

HIGH TEMPERATURE GATE VALVE

ACT High Temperature Service : (Model T)

The ACT High Temperature Gate Valve uses parallel expanding gate to obtain perfect shut off. The sealing is metal – to metal, both on the up and down stream of the valve, and unaffected by vibration and heat. API 6A gate valves provide positive shut-off of fluids and gases under extreme service conditions. The valve is the standard Model ‘E’ gate valve, modified with extended bonnet and stem to place the stem packing outside the critical heat zone. Other features and trim chart shall remain the same for model ‘E’ gate valves. We are the leading API 6A gate valve manufacturer producing valves with critical edge technology so as to provide efficient mechanism in-turn helps us in meeting our client’s demands efficiently.