AS1-XHP MECHANICAL PACKER

Actinc usa

2018-12-06T09:24:01+00:00

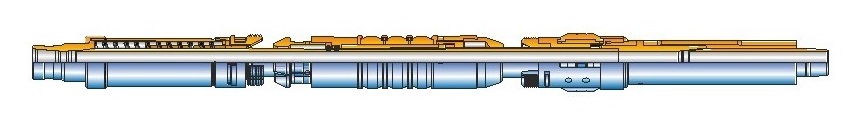

AS1-XHP MECHANICAL PACKER

The ACT AS1-XHP Packer is the most versatile of the mechanically set retrievable packers and may be used in any production application. Treating, testing, injecting, pumping wells, flowing wells, deep or shallow, the AS1-XHP is suited. The packer can be left in tension or compression, depending on well conditions and the required application. A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set and opens prior to releasing the upper slips when retrieving to allow pressure equalization.

The J-slot design allows easy setting and releasing; 1/4 turn right-hand set, right-hand release. A patented upper-slip releasing system reduces the force required to release the packer. A non directional slip is released first, making it easier to release the other slips. The AS1-XHP packer can withstand 10,000 psi (69 MPa) of differential pressure above or below.

FEATURES, ADVANTAGES AND BENEFITS:

-

The design holds high differential pressure from above or below, enabling the packer to meet most production, stimulation, and injection needs

-

The packer can be set with compression, tension, or wire line, enabling deployment in shallow and deep applications

-

The packer can be set and released with only a one-quarter turn of the tubing

-

The bypass valve is below the upper slips so that debris are washed from the slips when the valve is opened, reducing the times for circulation and total retrieval

-

The full opening enables unrestricted flow and the passage of wire line tools and other packer systems

-

The packer can be run with the T-2 on-off tool, which enables the tubing to be disconnected and retrieved without retrieving the packer

OPTIONS:

-

Elastomer options are available for hostile environments.

-

Optional safety releases are available.

SPECIFICATIONS:

| AS1-XHP MECHANICAL PACKER |

| CASING |

RECOMMENDED HOLE SIZE (inches) |

TOOL OD MAX. (inches) |

TOOL ID MIN. (inches) |

THREAD CONNECTION BOX UP / PIN DOWN |

PART NO. |

| SIZE (inches) |

WEIGHT (lbs ft) |

| 4.1/2 |

13.5-15.1 |

3.826-3.920 |

3.650 |

1.938 |

2.3/8” EUE |

261-3650-XXXX |

| 5 |

11.5-15 |

4.408-4.560 |

4.125 |

1.938 |

2.3/8” EUE |

261-4125-XXXX |

| 5 |

18-20.8 |

4.154-4.276 |

4.000 |

1.938 |

2.3/8" EUE |

261-4000-XXXX |

| 5.1/2 |

14-20 |

4.778-5.012 |

4.625 |

2.00 |

2.3/8” EUE |

261-4625-XXXX |

| 5.1/2 |

14-20 |

4.778-5.012 |

4.625 |

2.38 |

2.7/8" EUE |

261-4625-XXXX |

| 5.1/2 |

20-23 |

4.670-4.778 |

4.500 |

2.00 |

2.3/8” EUE |

261-4500-XXXX |

| 5.1/2 |

20-23 |

4.670-4.778 |

4.500 |

2.38 |

2.7/8" EUE |

261-4500-XXXX |

| 6.5/8 |

20-24 |

5.921-6.094 |

5.750 |

3.00 |

3.1/2”EUE |

261-5750-XXXX |

| 7 |

17-26 |

6.276-6.538 |

6.000 |

2.50 |

2.7/8" EUE |

261-6000-XXXX |

| 7 |

17-26 |

6.276-6.538 |

6.000 |

3.00 |

3.1/2” EUE |

261-6000-XXXX |

| 7 |

26-32 |

6.094-6.276 |

5.875 |

2.50 |

2.7/8" EUE |

261-5875-XXXX |

| 7 |

26-32 |

6.094-6.276 |

5.875 |

3.00 |

3.1/2” EUE |

261-5875-XXXX |

| 7 |

29-35 |

6.004-6.184 |

5.812 |

3.00 |

3.1/2” EUE |

261-5812-XXXX |

| 7.5/8 |

24-29.7 |

6.875-7.025 |

6.672 |

2.50 |

2.7/8”EUE |

261-6672-XXXX |

| 7.5/8 |

24-29.7 |

6.875-7.025 |

6.672 |

3.00 |

3.1/2” EUE |

261-6672-XXXX |

| 7.5/8 |

33.7-39 |

6.625-6.765 |

6.453 |

2.50 |

2.7/8”EUE |

261-6453-XXXX |

| 7.5/8 |

33.7-39 |

6.625-6.765 |

6.453 |

3.00 |

3.1/2” EUE |

261-6453-XXXX |

| 9.5/8 |

32.3-43.5 |

8.755-9.001 |

8.500 |

3.00 |

3.1/2” EUE |

261-8500-XXXX |

| 9.5/8 |

32.3-43.5 |

8.755-9.001 |

8.500 |

4.00 |

4.1/2" EUE |

261-8500-XXXX |

| 9.5/8 |

43.5-53.5 |

8.535-8.755 |

8.250 |

3.00 |

3.1/2” EUE |

261-8250-XXXX |

| 9.5/8 |

43.5-53.5 |

8.535-8.755 |

8.250 |

4.00 |

4.1/2" EUE |

261-8250-XXXX |

‘XXXX’ is changed as per material / elastomer / end connection