CALIBRATION & TESTING OF GAS LIFT VALVES

Actinc usa

2018-04-25T06:09:38+00:00

CALIBRATION & TESTING OF GAS LIFT VALVES

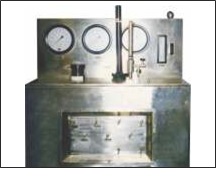

ACT GLV test bench is manufactured from heavy duty stainless steel sheet metal, pressure gauges with all stainless steel fittings and valves. The test bench is designed to meet most of the test / calibration requirements of API spec. 11 V1 for GLV’s. This is a combination of typical sleeve tester, typical encapsulated stem-seat leakage tester and also built-in pressure chamber (ager). Our GLV test bench provides testing facility for following parameters.

-

Charging bellows to specific nitrogen pressure

-

Valve opening pressure

-

Valve closing pressure

-

Valve leakage test

-

Hydrostatic valve test

DESIGN PARAMETERS

ACT Test Bench is designed in accordance with following design parameters as per API spec. 11 V1.

DESIGN PARAMETERS:

-

Valve Size: 1″ and 11/2″ conventional & retrievable nitrogen charged gas lift

-

System Accuracy: + 100 psi for aging chamber + 5 psi for calibration and charging of gas lift

-

Maximum Bellow Charge: 2000 psi

-

Maximum Chamber Hydro test: 5000 psi

-

Valve/Bellow Stabilizing /Storing Capacity: 10 nos (max.)

CONSTRUCTIONAL FEATURES OF GLV TEST BENCH

There are four sections of test bench as follows:

-

Gauge Section

-

Chamber Section

-

Control Valves Section and

-

Inlet Section