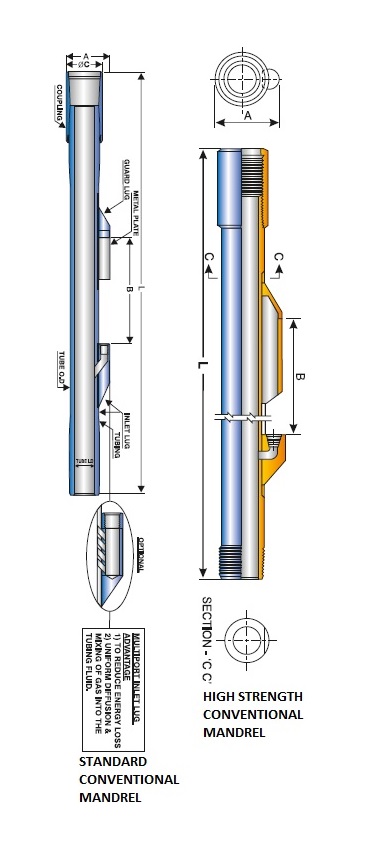

CONVENTIONAL MANDRELS

Actinc usa

2018-12-06T11:15:44+00:00

CONVENTIONAL MANDRELS

CONVENTIONAL MANDREL- SERIES 12 (Model: PCM-12)

Series 12 Mandrels are designed to receive any valve with a 1/2″ NPT inlet lug connection, a maximum OD of 1-1/16″, and a maximum length of 17.1/8″. Many tubing sizes, thread types and grades are available. Only the more popular grades and sizes are listed below.

CONVENTIONAL MANDREL-SERIES 12 (MODEL:PCM-12S)

Series 12 Mandrels are designed to receive any valve with a 1/2″ NPT inlet lug connection, a maximum OD of 1-1/16″, and a maximum length of 17.1/8″. Many tubing sizes, thread types and grades are available. Only the more popular grades and sizes are listed below. These Mandrels use shroud instead of Grand Lug & Metal Plate.

CONVENTIONAL MANDRELS-SERIES 15 (MODEL:PCM-15)

Series 15 Conventional Mandrels are designed to receive any valve with a 1/2″ NPT inlet lug connection, a maximum OD of 1-1/2″ and a maximum length of 29″. Many tubing sizes, thread types, and grades are available. Only the more poplular grades and sizes are listed below.

| SPECIFICATION OF STANDARD CONVENTIONAL MANDREL SERIES 12 (MODEL PCM-12) |

| Nominal tube size in |

Type thread |

OD of tube in |

Weight (PPF) |

ID of tube in |

A Max in |

B in |

L (ft) |

Approx weight (Lbs-f) |

Coupling OD c in |

Assembly Part No. Material Grade Api-N-80 |

| 2.3/8 |

EUE,8RD |

2.3/8 |

4.7 |

1.995 |

3.920 |

17-1/8 |

4 |

24.5 |

3.063 |

4C0-0601-100-00 |

| 2-3/8 |

EUE,8RD |

2.3/8 |

4.43 |

1.995 |

3.825 |

17-1/8 |

4 |

23.5 |

2.91 |

4C0-0601-100-01 |

| 2.3/8 |

NUE, 10RD |

2.3/8 |

4.6 |

1.995 |

3.840 |

17-1/8 |

4 |

23.8 |

2.875 |

4C0-0602-100-00 |

| 2-7/8 |

EUE,8RD |

2-7/8 |

6.5 |

2.441 |

4.490 |

17-1/8 |

4 |

34.0 |

3.668 |

4C0-0701-100-00 |

| 2.7/8 |

EUE,8RD |

2.7/8 |

6.0 |

2.441 |

4.330 |

17-1/8 |

4 |

32.0 |

3.460 |

4C0-0701-100-01 |

| 2.7/8 |

NUE,10RD |

2.7/8 |

6.4 |

2.441 |

4.400 |

17-1/8 |

4 |

33.9 |

3.5 |

4C0-0702-100-00 |

| 3.1/2 |

EUE,8RD |

3.1/2 |

9.3 |

2.992 |

5.125 |

17-1/8 |

4 |

42.0 |

4.5 |

4C0-0801-100-00 |

| SPECIFICATION OF STANDARD CONVENTIONAL MANDREL SERIES 12 (MODEL:PCM-12S) |

| Nominal tube size in |

Type thread |

OD of tube in |

Weight (PPF) |

ID of tube in |

A Max in |

B in |

L (ft) |

Approx weight (Lbs-f) |

Coupling OD c in |

Assembly Part No. Material Grade Api-N-80 |

| 2.3/8 |

EUE,8RD |

2.3/8 |

5.45 |

1.995 |

3.920 |

17-1/8 |

4 |

27.5 |

3.063 |

4C0-0601-100-00 |

| 2.3/8 |

EUE,8RD |

2-3/8 |

5.18 |

1.995 |

3.825 |

17-1/8 |

4 |

26.5 |

2.91 |

4C0-1601-100-01 |

| 2.3/8 |

NUE, 10RD |

2.3/8 |

5.35 |

1.995 |

3.840 |

17-1/8 |

4 |

26.8 |

2.875 |

4C0-0602-100-00 |

| 2.7/8 |

EUE,8RD |

2-7/8 |

7.25 |

2.441 |

4.490 |

17-1/8 |

4 |

37.0 |

3.668 |

4C0-1701-100-00 |

| 2.7/8 |

EUE,8RD |

2.7/8 |

6.75 |

2.441 |

4.330 |

17-1/8 |

4 |

35.0 |

3.460 |

4C0-0701-100-01 |

| 2.7/8 |

NUE,10RD |

2.7/8 |

7.15 |

2.441 |

4.400 |

17-1/8 |

4 |

36.9 |

3.5 |

4C0-1702-100-00 |

| 3.1/2 |

EUE,8RD |

3.1/2 |

10.05 |

2.992 |

5.125 |

17-1/8 |

4 |

45.0 |

4.5 |

4C0-0801-100-00 |

| SPECIFICATIONS OF STANDARD CONVENTIONAL MANDREL SERIES 15 (MODEL:PCM-15) |

| Nominal tube size in |

Type thread |

OD of tube in |

Weight (PPF) |

ID of tube in |

A Max in |

B in |

L (ft) |

Approx weight (Lbs-f) |

Coupling OD c in |

Assembly Part No. Material Grade Api-N-80 |

| 2.3/8 |

EUE,8RD |

2.3/8 |

4.7 |

1.995 |

4.577 |

29 |

4 |

27 |

3.063 |

4C2-3601-100-00 |

| 2.3/8 |

EUE,8RD |

2.3/8 |

4.43 |

1.995 |

4.375 |

29 |

4 |

26 |

2.91 |

4C2-3601-100-01 |

| 2.3/8 |

NUE, 10RD |

2.3/8 |

4.60 |

1.995 |

4.484 |

29 |

4 |

26.4 |

2.875 |

4C2-3602-100-00 |

| 2.7/8 |

EUE,8RD |

2.7/8 |

6.50 |

2.441 |

5.130 |

29 |

4 |

36.5 |

3.668 |

4C2-3701-100-00 |

| 2.7/8 |

NUE,10RD |

2.7/8 |

6.40 |

2.441 |

5.046 |

29 |

4 |

36.3 |

3.50 |

4C2-3702-100-01 |

| 3.1/2 |

EUE,8RD |

3.1/2 |

9.30 |

2.992 |

5.859 |

29 |

4 |

44.5 |

4.50 |

4C2-3801-100-00 |

| 3.1/2 |

NUE,10RD |

3.1/2 |

8.98 |

2.992 |

5.734 |

29 |

4 |

43.6 |

4.25 |

4C2-3801-100-00 |

NOTE: Using 2-3/8″ EUE,8RD tubing inside 4-1/2″ casing. The mandrel contains a shroud to provide valve protection.

HIGH STRENGTH CONVENTIONAL MANDRELS

HIGH STRENGTH CONVENTIONAL MANDREL-SERIES 502 (Model: PHSCM-502)

ACT has been manufacturing high strength conventional mandrels. Their round ex terior design makes them easy to rotate in difficult situations & perform easier washover operations. These mandrels exceed N-80 tubing strength.

ACT’S high strength mandrels have the benefit of:

-

Can with stand pull load of over 60 Metric Tones.

-

Tested hydraulically to 8000 PSI.

Series 502: These are designed to receive any valve with 1/2″ NPT & a maximum OD of 1-1/2″.

All above series are available in many tubing size, thread size & grades, only the more popular sizes are listed below.

| SPECIFICATIONS OF HIGH STRENGTH CONVENTIONAL MANDREL SERIES 502 |

| Nominal tube size in |

Type thread |

OD of tube in |

ID of tube in |

A Max in |

B in |

L (ft) |

Approx weight (Lbs-f) |

Coupling OD c in |

Assembly Part No. Material Grade Api-N-80 |

| 2.3/8 |

EUE,8RD |

2.594 |

1.995 |

4.577 |

29 |

4 |

35.5 |

3.063 |

502-3601-100-00 |

| 2.3/8 |

EUE,8RD |

2.594 |

1.995 |

4.375 |

29 |

4 |

34.5 |

2.91 |

502-3601-100-03 |

| 2.7/8 |

EUE,8RD |

3.094 |

2.441 |

5.130 |

29 |

4 |

43.0 |

3.668 |

502-3701-100-00 |