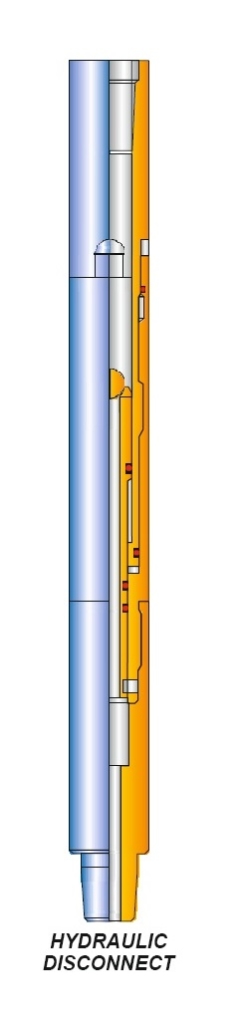

HYDRAULIC DISCONNECT

Actinc usa

2018-12-07T06:54:38+00:00

HYDRAULIC DISCONNECT

The Hydraulic Disconnect allows the toolstring to detach at a predetermined point via the deployment of a suitable drop/trip ball through the coiled tubing. The drop ball locates on a piston sleeve creating sufficient back pressure to shear the pins and disconnect the tool. All piston sleeves and drop balls are returned to surface leaving a standard ‘GS’ internal fish neck for retrieval purposes.

| HYDRAULIC DISCONNECT |

| Max. |

Min. |

Tensile |

Fish Neck |

Make-up |

Drop Ball |

Internal |

| O.D. |

I.D. |

Strength |

(internal) |

Length |

Release |

Ball |

| (in) |

(in) |

(Standard |

|

(in) |

(in) |

Clearance |

|

|

Service) |

|

|

|

(in) |

| 1.687 |

0.438 |

40,000 LBS |

2” 'GS' |

18 |

5/8 |

7/16 |

| 1.750 |

0.438 |

45,000 LBS |

2” 'GS' |

18 |

5/8 |

7/16 |

| 2.125 |

0.438 |

55,000 LBS |

2” 'GS' |

18 |

5/8 |

7/16 |

| 2.250 |

0.750 |

65,000 LBS |

2” 'GS' |

18 |

13/16 |

3/4 |

| 2.375 |

0.750 |

70,000 LBS |

2-1/2” 'GS' |

19 |

13/16 |

3/4 |

| 2.875 |

0.750 |

120,000 LBS |

3” 'GS' |

21 |

13/16 |

3/4 |

| 3.125 |

1.062 |

150,000 LBS |

3” 'GS' |

21 |

1.1/8 |

1 |