RELIEF VALVE

Actinc usa

2019-05-01T12:00:30+00:00

RELIEF VALVE

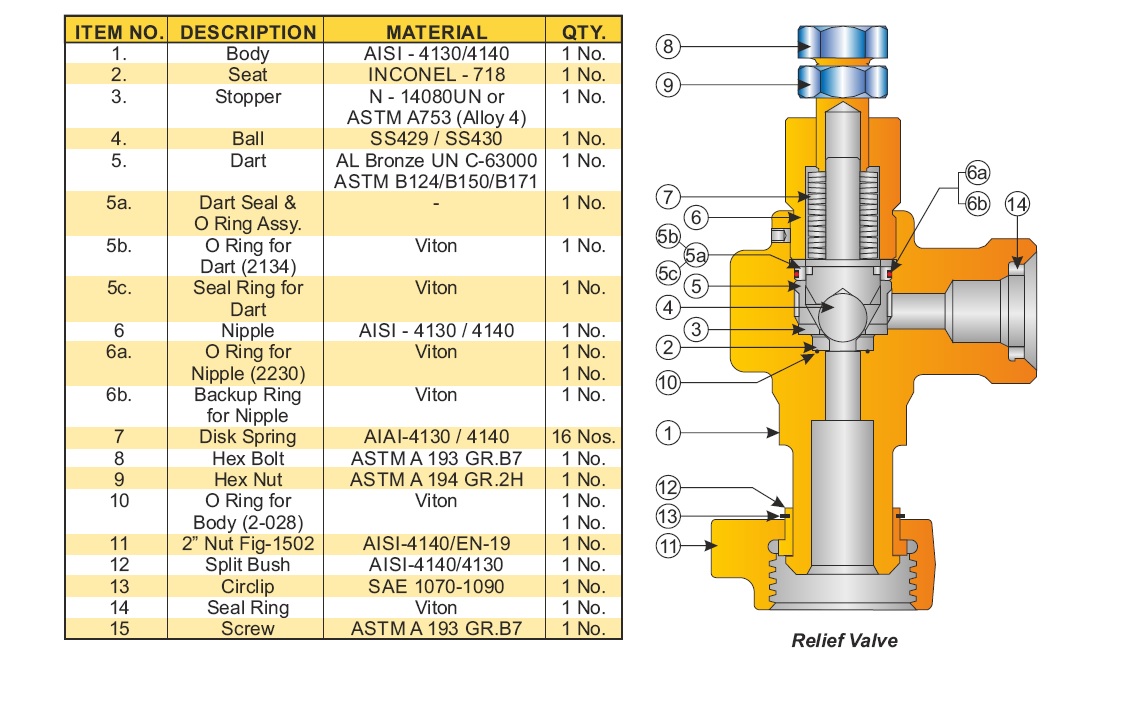

ACT relief valves are compact and simple to operate, providing over pressure protection for typical applications such as reciprocating pumps and treating lines. Compact and simple to operate, the valves are direct acting, relying on the system’s hydraulic pressure to overcome a preset spring force to relieve. They are externally adjustable from zero pressure to maximum setting. Manufactured to ACT Oil & Gas stringent Quality Assurance System, all pressure bearing components are made from high quality material. The forged body features an integral wing union male inlet, suitable for the pressure rating of the component.

The operation of the ACT’s back pressure relief valve is a simple balance between the spring loaded keeper which holds the ball in the seat and the inlet liquid pressure acting on the ball. The spring pressure is set by tightening the hex bolt on top which pushes on the keeper. This in turn compresses the springs that forces the keeper on the Ball. When the inlet fluid pressure rises and overcomes the set spring pressure, the ball is lifted off its seat thereby discharging fluid to the outlet end. Once the pressure of the inlet fluid falls below the set spring pressure, the ball will be pushed back on to its seat and the fluid can pass downstream.

-

End connections are standard Fig. 1502 union ends

-

Opens when a pre-set pressure is exceeded and automatically snaps shut when pressure drops

-

Comes standard with Material Test Reports (MTR)

-

Suitable for standard service applications up to 15,000 psi working pressure and sour gas service up to 10,000 psi working pressure

Note: Valves are set at 15,000 psi unless otherwise specified by the customer.

ACT manufacture high pressure relief valve in sizes 1” fig.1502, 1 1/2” fig.1002, 1 1/2” fig.1502, 2” fig.1502, 2 1/2”, fig.1002, 3” fig.602, 3” fig.1502, fig.602, 4” fig.1002 etc.