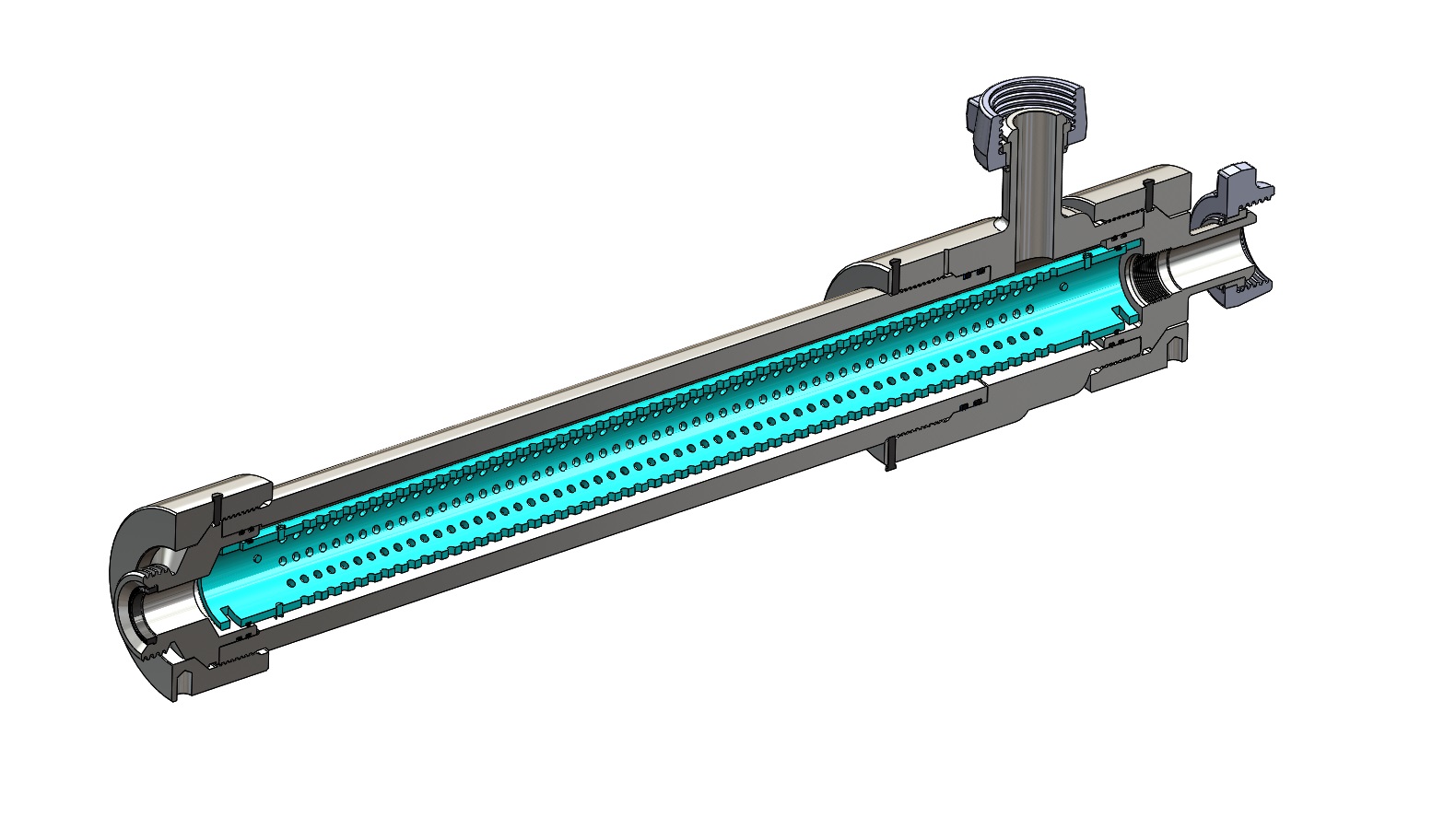

TRASH/DEBRIS CATCHER WITH SIDE OUTLET ASSEMBLY

Actinc usa

2019-05-01T06:55:29+00:00

TRASH/DEBRIS CATCHER WITH SIDE OUTLET ASSEMBLY

PRODUCT DESCRIPTION

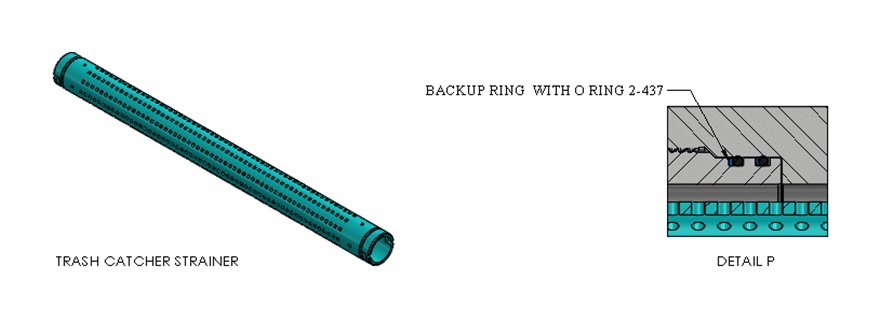

The debris catcher is designed to recover large solid pieces. Debris/Trash catchers are normally positioned upstream of the choke manifold to prevent erosion damage to downstream equipment. This piece of equipment is usually placed just downstream of the well head and just upstream of the choke manifold so it is the first piece of equipment that the well effluent is passed through. This piece of equipment is vital in prolonging downstream equipment such as choke manifold, line heaters, sand separators and test separators. Our standard trash catcher design flows in at 3” Fig 1502 and flows out at 2” Fig 1502 or 3” fig 1502 to handle normal flowback operations. Customizable design options are available upon request.

FEATURES OF DEBRIS/TRASH CATCHER

-

Various sizes of screens available.

-

Dual catcher screen allows for continuous screening.

-

Bypass line available

-

Offers the convenience of being able to change screens without interrupting flow back.

-

With customizable options, our debris catchers are rated for 10,000 or 15,000 CWP. Depending on your requirements we can use different styles of crossovers and pup joints to get the solution you need.

-

Our trash catchers have zero welding on all of the high pressure iron. This safety feature prevents micro cracking that is often found in welding heat treated metals.

-

All parts are manufactured from the highest quality material with stringent quality control checks. All parts undergo NDT testing as per API standards and Internal Quality procedures.

-

Trash catcher assembly is tested at 1.5 times the max. CWP pressure.

-

Rated for both Sweet and sour conditions

-

Plug valve or/and gate valve based design

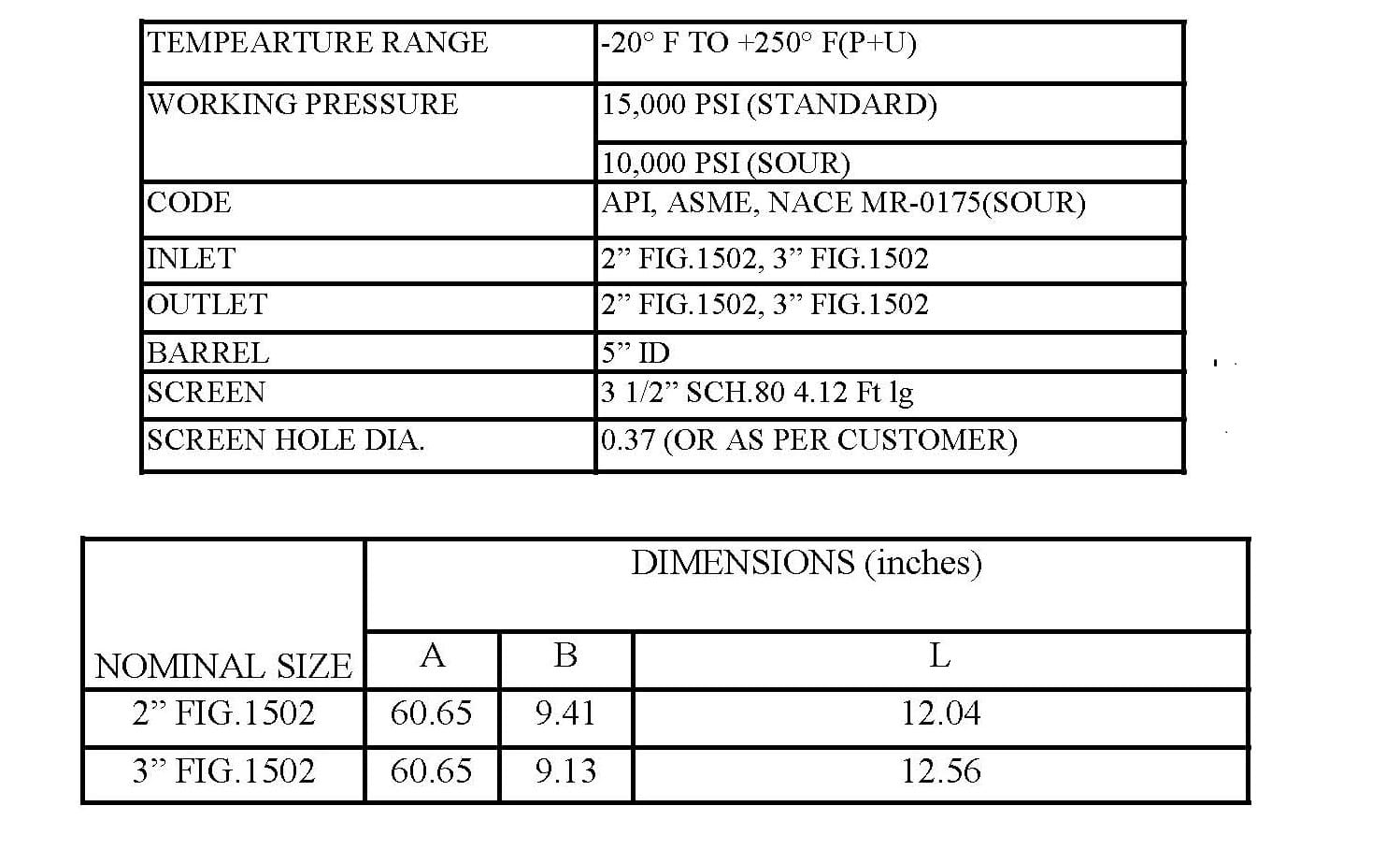

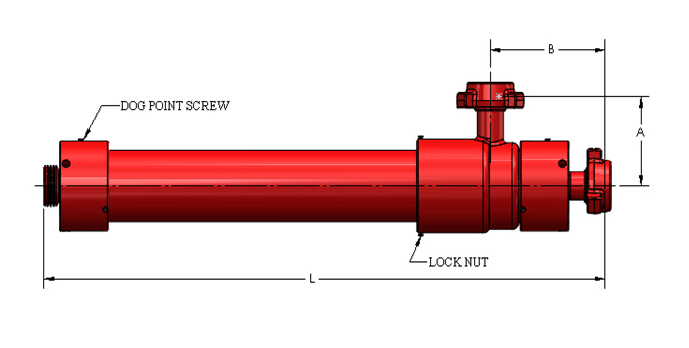

OPERATING SPECIFICATIONS