Gate Valves, Chokes, Manifolds

Actinc usa

2019-05-01T12:25:29+00:00

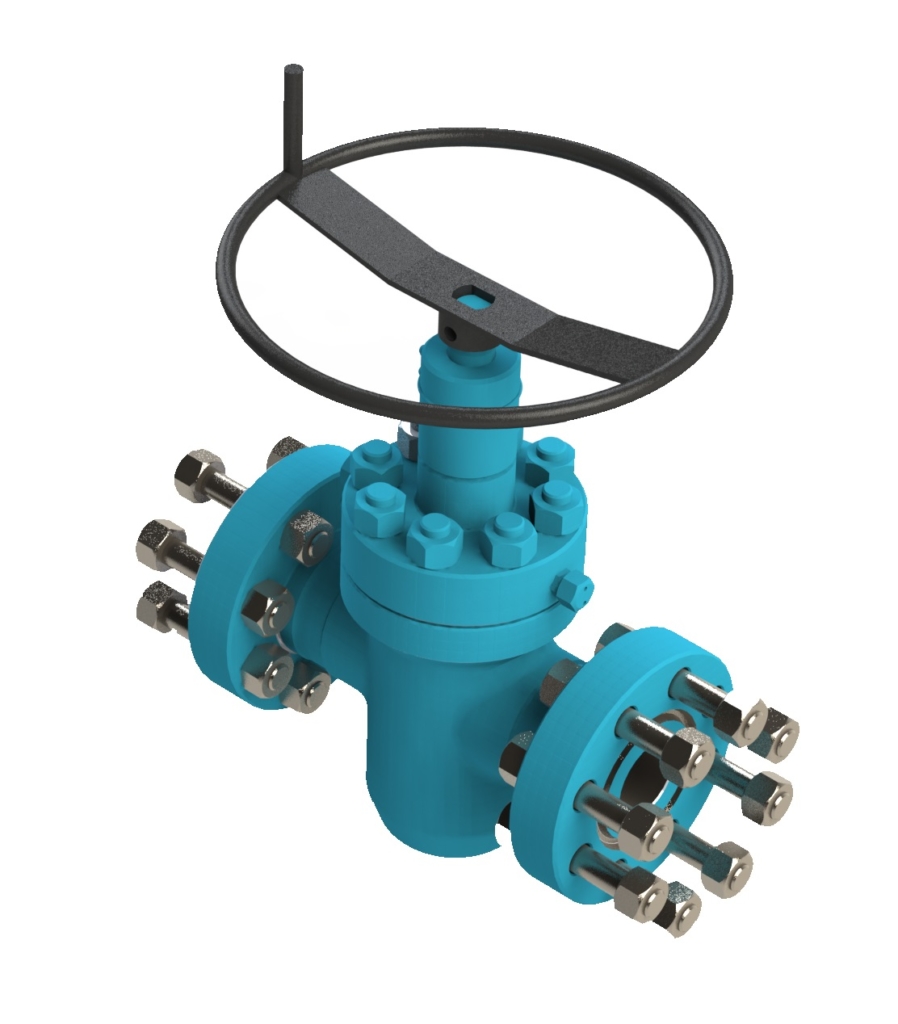

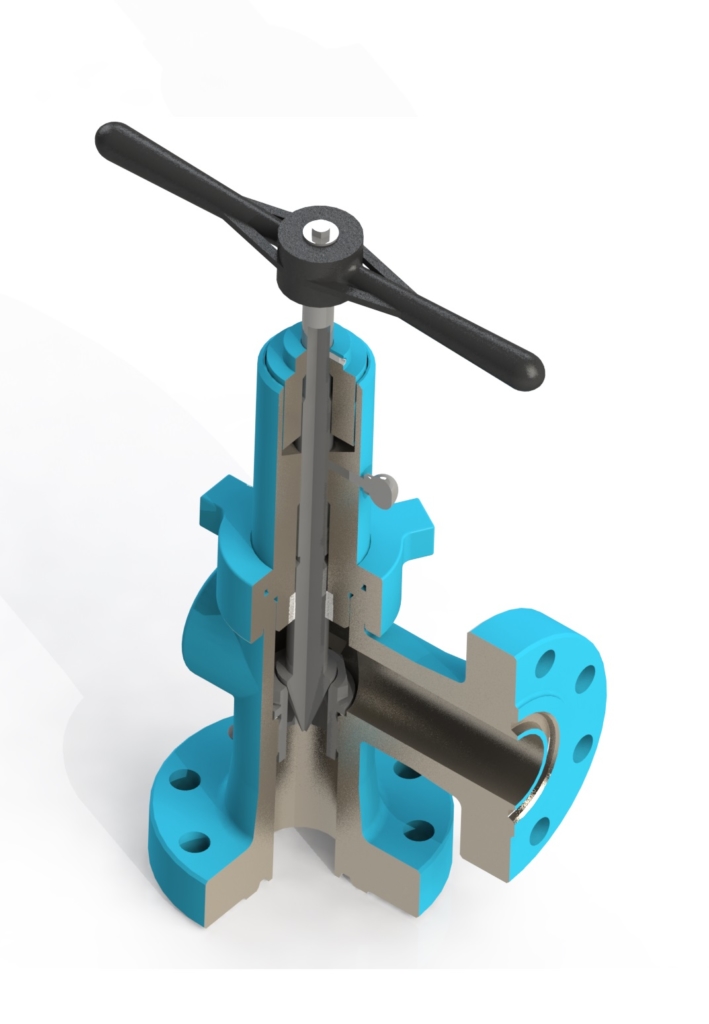

GATE VALVES

ACT manufactured Gate Valves required for drilling and production operation. These are the main features of gate valves :-

-

Full bore through conduit

-

Block Mechanism & Bleed Mechanism

-

Long-life seat

-

In-line Maintenance

-

Metal to Metal sealing

CHOKE VALVES

ACT manufactures both Positive and Adjustable Choke Valve in pressure rating up to 15,000 PSI WP with different styles of end connection. Adjustable Chokes Valve are meant for variable flow. They have externally controlled indicator showing orifice size in the increment of 1/64th inch.The variation in choke valve size is achieved by rotating hand wheel to obtain desired flow rate at down stream side.

PLUG VALVES

ACT valve bodies are made from alloy steel forgings which are designed to variety of end connections to be integrally machined.ACT plug and inserts are designed to resist abrasion and corrosion.ACT valves can be easily adopted for hydraulic or pneumatic These configurations are designed for integration with complete manifold systems.

CHECK VALVES

ACT Check Valves are flow control devices that permit flow in one direction, but stop flow in the opposite direction. These check valves are used generally in well service applications and are placed in the treating line to allow to the well, but isolate any back flow.

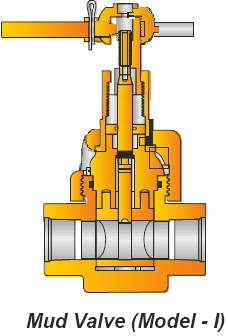

MUD VALVE

ACT Mud Valves are Forged/Cast exclusively made for mud, cement, fracturing water and steam abrasive applications. All valves are hydrostatic shell and seat tested in accordance with the API 6A /API 6D specifications. Valves are specially designed for oil-field applications like Manifolds, Pipe Line, Crude Oil and Sour Gas Line, Well Treating Chemical, Drilling Chemical, Water Flood Lines, Abrasive Drilling Mud etc.

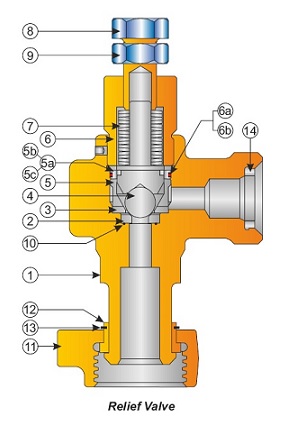

RELIEF VALVE

ACT relief valves are compact and simple to operate, providing over pressure protection for typical applications such as reciprocating pumps and treating lines. Compact and simple to operate, the valves are direct acting, relying on the system’s hydraulic pressure to overcome a preset spring force to relieve. They are externally adjustable from zero pressure to maximum setting.

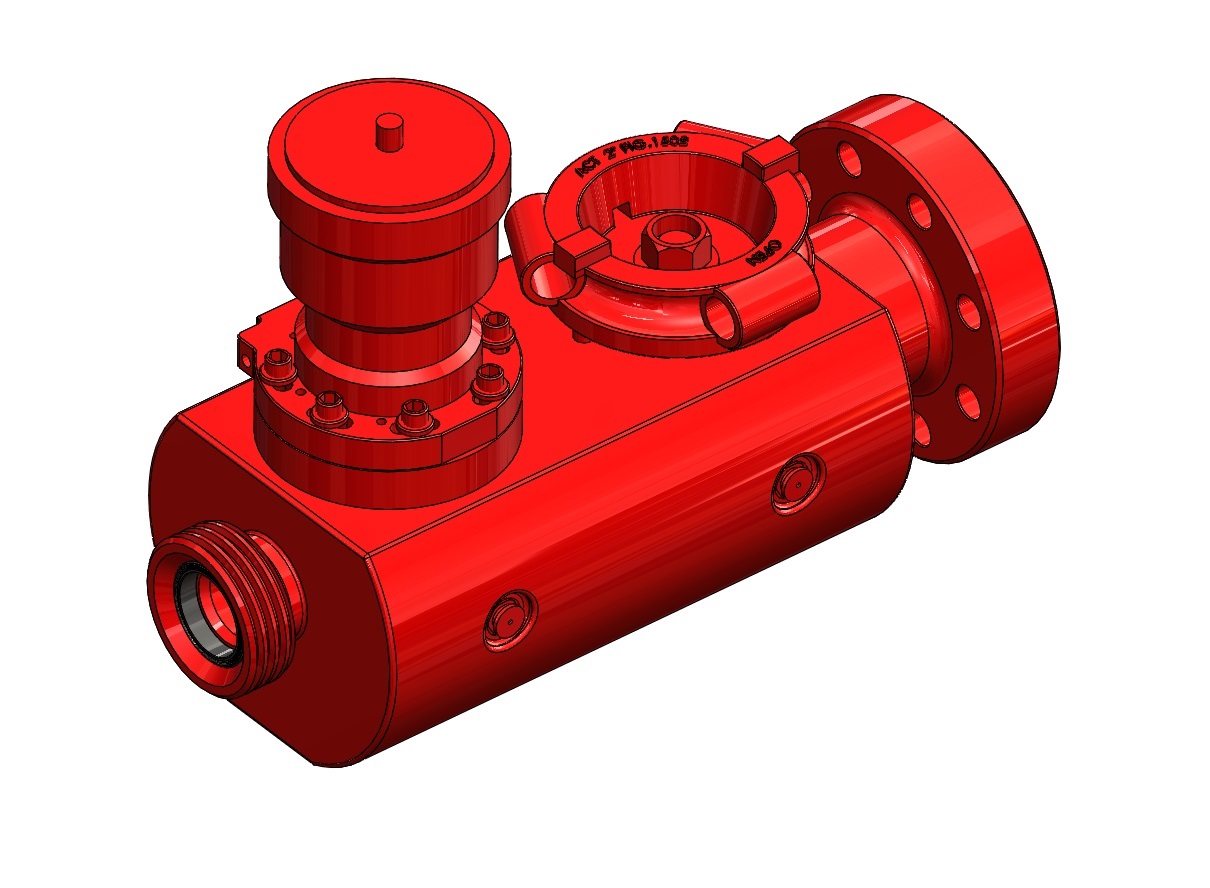

DUAL PLUG VALVE

These valves are used where back to back plug valves are required but there is limitation of space. Connections include union x flange, flange x flange and union x union. Dual body plug valave Can be provided with union connection or flange connection. The flow path between the plug interface and seat segment eliminates body erosion and limits any potential wear to replaceable components.

FLANGES

ACT manufactures all types of Forged Flanges such as Weldneck, Slip-on, Socket Weld, Threaded, Lapped and Blind as per ANSI B-16.5 & ASA B-16.5, covering sizes from 1/2″ to 24″, pressure ratings from class 150 to 2,500 and temperature rating -200 F to 15000. Studs, Nuts and Gaskets for these Flanges are also provided.

CEMENTING HEAD

ACT Cementing Head is used for cementing the annular space between casing and bore hole during 2nd stage of well construction cycle. The Cementing Head is employed to connect the pumps of the cementing trucks to the casing string and provides access for insertion of the cementing plugs.

SINGLE COMPLETION COMPONENT

ACT Cementing Head is used for cementing the annular space between casing and bore hole during 2nd stage of well construction cycle. The Cementing Head is employed to connect the pumps of the cementing trucks to the casing string and provides access for insertion of the cementing plugs.